Pulse Venturi Blowing Bag Filter |

Homepage > Products > Dust collector for cupola |

Pulse Venturi Blowing Bag Filter

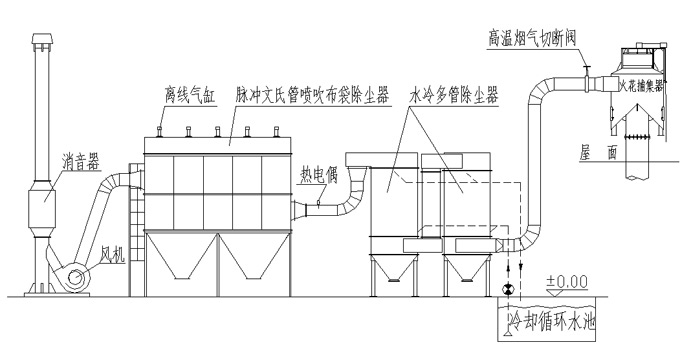

Pulse venturi blow bag filter is invented on the basis of box type pulse reverse blow bag filter, which has the advantages of better dust collection effect, better cleaning effect and wider usage than box type pulse reverse blow bag filter. This kind of bag filter can achieve better dust collection effect when the cupola furnace is used in the condition of high smelting efficiency, long smelting time and more impurities inside the row materials.

The main construction difference between pulse venturi blow bag filter and box type pulse reverse blow bag filter is the venturi. Each bag of venturi blow bag filter is installed a venturi, by which the dust layer on the surface of bag can be cleaned more clearly under the compressed air. Meanwhile, a lot of pulse solenoid valves should be used because of the function of venturi blow, which also make the maintenance work more difficult because if you want to replace the bag you should dismantle the solenoid valve first. On the other hand, the additional maintenance work due to additional venturi design should be ignored contrast to the better dust collection effect.

The features of pulse venturi blow bag filter are shown as below.

① The dust collection efficiency will be higher than 99.5% and the dust concentrations of emission can be lower than 30mg/Nm3, which is better than box type pulse reverse blow bag filter.

② Pulse venturi blow bag filter can be used to collect non cellulose dry dust and can be widely applied in dust collection of metallurgy industry, foundry industry, building materials industry, cement industry, gain processing industry, pharmaceutical industry, chemical industry and etc.

③ The manufacture of pulse venturi blow bag filter can be modularized into small modules, which makes the installation very convenient.

④ Pulse venturi blow bag filter is controlled by PLC, which makes the system stable and reliable.

- 2018-01-04 > Vacuum casting equipment

- 2018-01-03 > 4~5t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola

- 2018-01-03 > 7~8t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row cold air supply cupola

- 2018-01-03 > 10~30t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola