Vacuum system |

Homepage > Products > Vacuum casting equipment |

Vacuum system

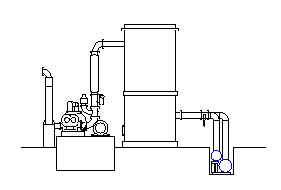

Advantages: It can be operated under both high pressure and low pressure. Moulding and keeping pressure are under low pressure, and pouring is under high pressure, this can save energy obviously. Stable pressure tank bag dust collector is set on the entrance, it not only can steady pressure but also can collect dust, and make sure dust sand not enters into pump, so that service life can be improved. It doesn’t need a specially cooling pool, and save space.

Disadvantages: The cost of investment is relatively high.

Water-cycle vacuum pump

Advantages: The investment cost is higher than that of roots vacuum pump.

Disadvantages: Consume much power when operate under high pressure. It is easy to be influenced by temperature, the quantity of extracted steam will not be sufficient because of the deduction of water vapor pressure, and vacuum degree can not reach the requirement. The dust sand will easily enter into the body part of pump, the rotor and the pump body are easy to wear and seriously affect the service life. The stability is relatively poor, the maintenance cost and using cost are relatively high.

ln consideration of advantages of roots vacuum pump, our company recommends the use of high and low pressure vacuum pumps with high and low pressure vacuum pipes. Using high pressure when pouring, and moulding and keeping pressure are under low pressure. Frequency conversion control can greatly save electric energy and reduce production cost. The diameters of the high and low pressure vacuum pipelines are designed according to the size of the vacuum system.

(This product has been applied for a patent.)

Vechicle mounted vacuum pump (It is applied for a patent)

This vechicle mounted vacuum pump is installed on the crane, so the vacuum system moves along with crane. In this way, there is no need to move vacuum hose on the ground and aviod leakage when switch vacuum pipes. At the same time, it can prevent the vacuum pipe abscission when pipes dragged on the ground and make mould box scrap.

Without vacuum pipes dragged on the ground, the space among stations can be reduced, and effective area of workshop can be improved. In this way, the production of workshop will be increased. It can greatly reduce workers' labor intensity, reduce operators, improve safety in production and eliminate potential safety hazards.

- 2018-01-04 > Vacuum casting equipment

- 2018-01-03 > 4~5t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola

- 2018-01-03 > 7~8t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row cold air supply cupola

- 2018-01-03 > 10~30t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola