Sand preparation |

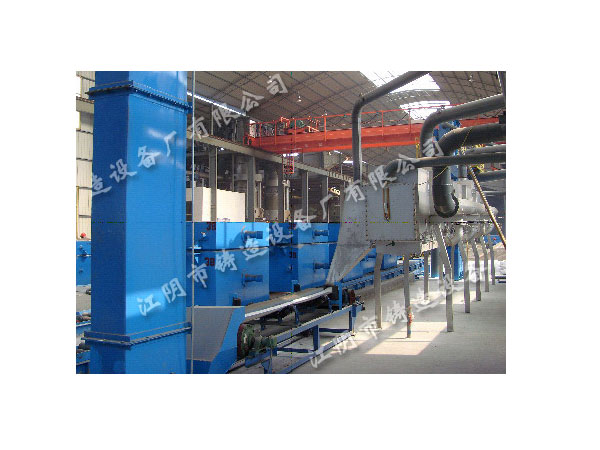

Homepage > Products > Vacuum casting equipment |

Sand preparation

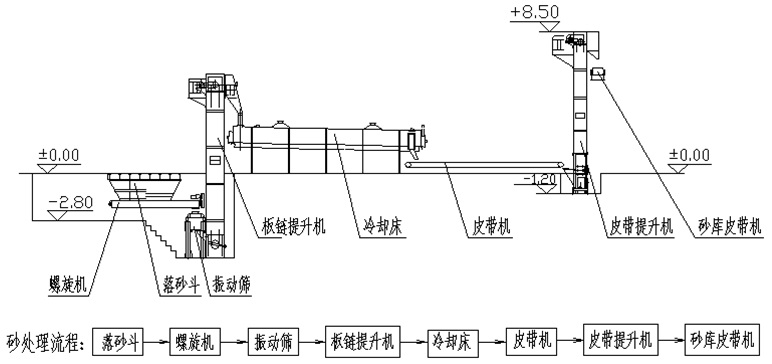

1, Shakeout device

When the casting matches the technical process, hoisting the flask and casting to shakeout device. After coarse filtration, the debris is intercepted on the shakeout device, high temperature sand passes through a rotating conveyor and enters the vibrating screen.

2, Rotating conveyor

The rotating conveyor is a key equipment to ensure the normal operation of the whole sand preparation system, and plays the role of quantitative transportation. In order to make sure the cooling effect of sand, rotating conveyor transports the high temperature sand (up to above 500 degrees centigrade) to vibrating screen for sieving in a uniform and quantitative way.

3, Vibrating screen (It is applied for a patent)

After sieving the impurities, the vibrating screen sends high temperature sand into the heat-resisting elevator. The vibrating motor is manufactured by Zhongxiang, Hubei. The column is made of 250x250x10 rectangular tube, which is sturdy and stable.

4, Heat-resisting elevator

The chain and chain wheel of this elevator are made of alloy steel, the transmission mechanism is original Sumitomo reducer, and is specially designed for high tenmperature sand fo V-process, which is durable and reliable. Heat-resisting elevator sends high temperature sand to cooling bed.

5, Cooling bed (It is applied for a patent)

Our cooling bed is a key equipment of sand preparation system and is specially designed for V-process. Cooling equipment of V-process can not be used any other devices, especially the boiling cooling bed. Sand inside the equipment is not in a state of boiling, but in a flow state with gas-solid two-phase, it full contacts with cooling water pipe for heat exchange. So that the cooling efficiency is great, and abrasion of cooling water pipe is much less than that in s boiling state, at the same time, the energy consumption is much smaller and service life is long.

When the high temperature sand (up to above 500 degrees centigrade) enters into cooling bed, it is effectively cooled to meet the requirements of process (50~55℃), and is discharged through belt conveyor, bucket elevator, another belt conveyor to sand hopper and ready for use.

6, Chain elevator

The cooled sand is hoisted to the belt conveyor on the platform of bucket elevator and sand hopper by the chain elevator. Then it is diacharged into sand hopper to stand by.

t out and notifies to add sand. Otherwise, the molding line will stop working automatically.

When the sand is in the middle positon, there will be a sound and light alarm notification, the staff needs to add sand immediately, if not, the left sand will not run for a long time.

When the sand is added to the upper position, the tripper will stop discharging and change to the next unloading station, Only when all the upper positions are full, the sand adding system will stop working automatically.

This sand preparation system is fully automatic controlled, without any staff operation (except for pressing one button when adding sand).

7, Blet conveyor

- 2018-01-04 > Vacuum casting equipment

- 2018-01-03 > 4~5t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola

- 2018-01-03 > 7~8t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row cold air supply cupola

- 2018-01-03 > 10~30t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola