Molding system |

Homepage > Products > Vacuum casting equipment |

Molding system

The film heater designed by our company is used specially for heating EVA film, it grabs the film firstly and then heats and dries. Resistance wire heating supplies heat, which has more heat, adjustable power, uniform film heating and long service life. This way is also widely adopted abroad. According to the requirements of casting process, our film heater combines with drying function, which has been applied for a nationnal patent. The driving device of this film heater is Sumitomo inverter motor, which has accurate positioning and long service life, its operation is all controlled by program which is simple and convenient, we just press one button when operating.

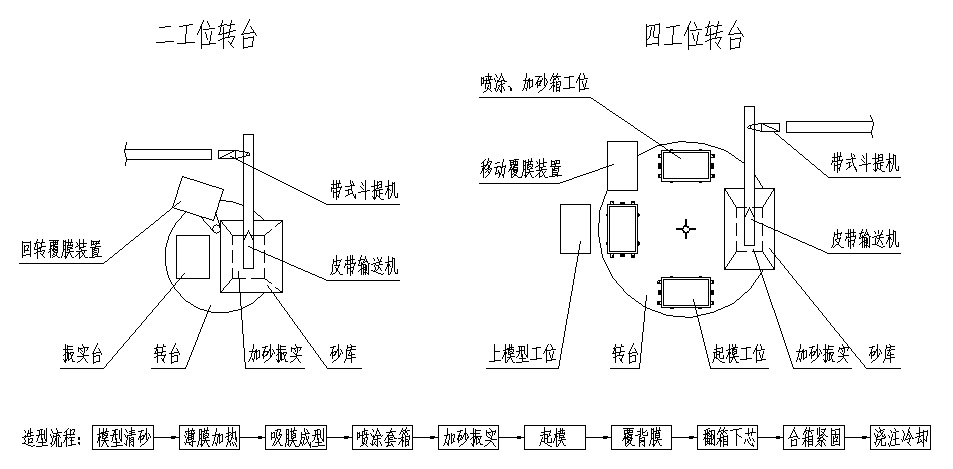

V-process molding line of our company is composed of five systems, which are molding system, sand preparation, vacuum system, dust collecting system and water circulating system.

1, Sand hopper

The sand hopper designed by our company can guarantee the production of sand for more than 5 hours, and can store 80~500 tons sand. Therefore, there is no intermediate sand hopper in our production line, which brings great convenience to the management and reduces the area of workshop, and also saves a lot of investment cost and maintenance management cost.

The main column of the sand bucket of our company is made by 250 x 250 x 10 rectangular tubes, the body part is welded by 20# channel steel and t8 steel plate, there are three layers of tension bars in the middle, which can make sure full the sand hopper is not deformed whenever it is full or empty. Pressure relief device inside sand hopper takes all the weight of sand, if there is any deformation on the sand hopper, the film heater and horizontal switch will not cause failure.

2, Horizontal Switch

With pneumatic switch, no matter what size of the flask, horizontal switch can fill up the flask evenly and quickly. And the flask itself is a quantitative device,there’s no need to add any quantitative measures or equipment.

The size of horizontal switch is designed according to flask size.

3, Film Heater

Resistance wire heating supplies heat, after heating the EVA plastic film to a required temperature (in less than 1 minute), the cylinder declines, the EVA plastic film is covered on the pattern, then the movable film frame rises and replaces. If supplied heat by heating quartz tube, the heat efficiency is poor and the heating time is much longer (5~8 minutes).

The driving device of film heater is frequency control deceleration motor, it is running among the workstations and can reach any station as the requirement, which makes operation convenient and reliable.

The power of resistance wire is adjusted by one time accroding to the requirement, thus it is convenient and quick when debugging and can be operated automatically and manually.

The driving device is made by Sumitomo in Japan, it has accurate positioning and long service life, its operation is all controlled by program which is simple and convenient, we just press one button when operating.

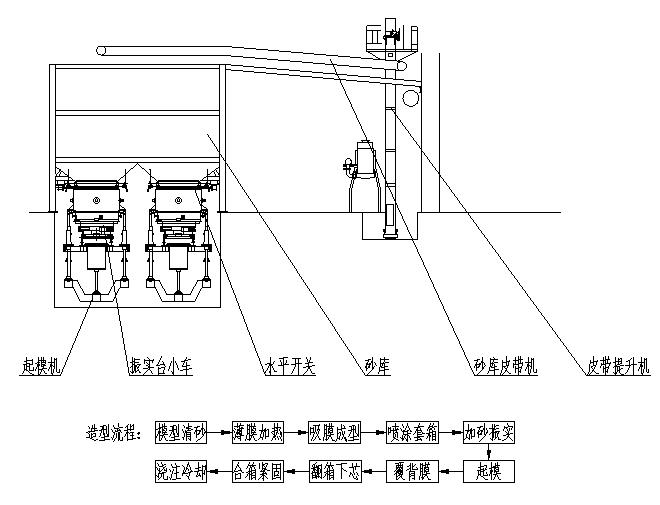

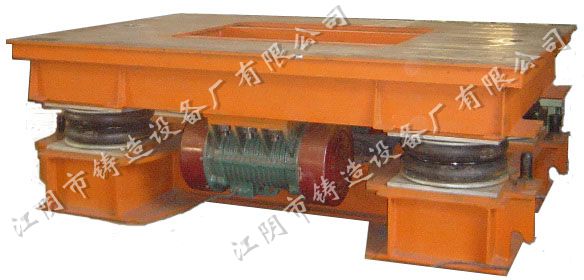

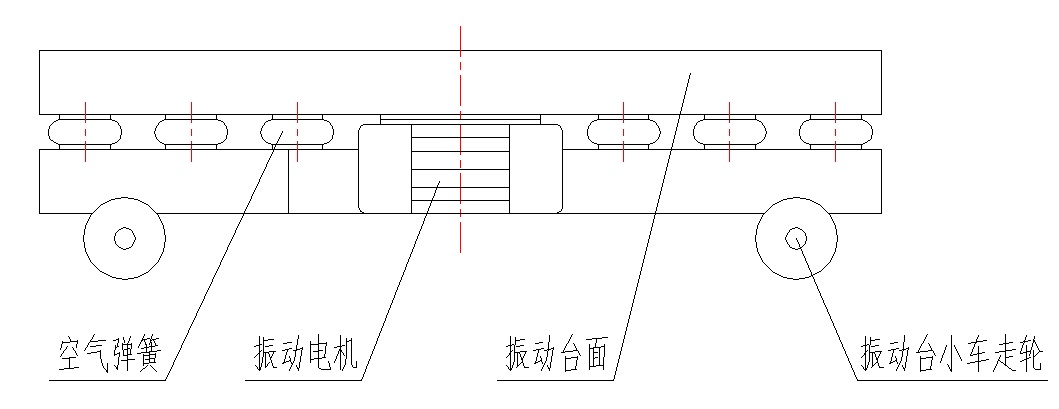

4, Movable vibrating table

It can compact the molding sand, and transport it to heating station and stripping station by using a frequency control deceleration motor as the driving device.

Choose the right air spring according to the weight you want to carry, only 4 air springs are needed which is used for shock absorption, and there is no requirement for the foundation.

The vacuum hoses, signal lines and cables are arranged in the plate, this way ensures the safety and reliability of the molding line.

The platform size of vibrating table is designed on the basis of flask size.

Platform size 3800x2200

Platform size 2600x1750

The maximun platform size designed by our company is 3100×3900, whose exciting force can be 30 tons, and the weight of flask and sand can be 20 tons,.

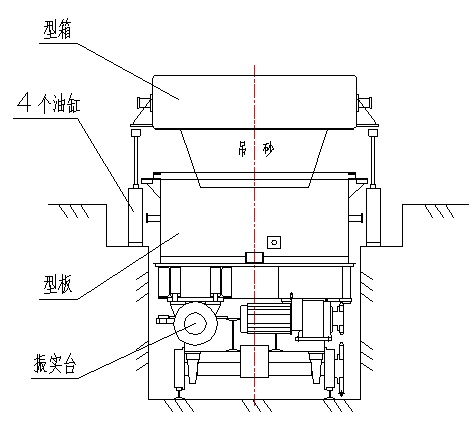

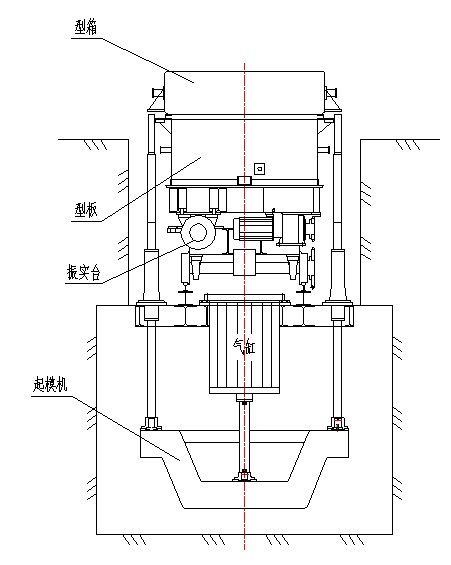

5, Stripping machine

Our stripping machine has a super large cylinder, whose body part is fixed by four guide rods, that makes them synchronous. The diameter of the rods is more than 120 millimeters, the rods are needed chrome-plating and polishingtrratment after tempering processing. Generally, the stripping machine can jack up flask of 10~30 tons, and service life of it can be infinite.

The comparison of different design stripping machine

Unreasonable design our design

It is impossible to ensure the equal distance and the same speed among the four guide rods by using four cylinders, the machine will inevitably roll and destroy the cavity. While, this situation can be avioded when the four guide rods are controlled by one cyliner.

6, Automatic molds turnover machine by using manipulator

a) The manipulator turnover machine of our company has been applied for a national patent.

It consists of a turning platform, a manipulator, a turning device, a trolley system, pneumatic control (or hydraulic control), and PLC electronic control, etc. It can effectively improve the degree of automation and the precision of assembling the flasks, and also can avoid the damage of cavity. That reduces the labor intensity and saves the labor force.

A frequency control deceleration motor is the driving device, when a trolley runs to stripping station of drag flask, manipulator starts to strip (no needing stripping machine), and turnovers the drag flask at the assembling station. Then manipulator runs to stripping station of cope flask and strips. Assembling cope and drag flasks finally.

This manipulator turnover machine operates stably and reliably, and can be accurate positioning with low operating requirements for the workers.

b) Different types of manipulator molds turnover machine

Advantages: The vacuum condition can be automatically switched, no need for artificial plugging vacuum hoses.

Disadvantages: The structure is complex and the manufacturing requirements of flask, plate and other equipment are high. Because the vacuum tube is automatically absorbed and switched, it is easily made leakage of the suction surface , and it can cause the collapse of the flask if the situation is serious. The precision of the assembling flasks is relatively difficult to be guaranteed, it may cause the failure of assembling flasks. The requirement of worker’s operation is high, and the manufacturing cost and the use cost are also relatively high.

c) It also can be turnovered by manipulator and artificial assembled by using crane.

Using a frequency control deceleration motor as driving device, the operation is easy, relaible and easy to be adjusted. The manufacturing requirement of flask is low, and the investment is low, too.

7, Pneumatic control

Import SMCproducts from Japan, which is reliable and had long service life. (the longest usage in Chain has been in normal use for nearly 20 years)

8, Electronic control

It is controlled by PLC program, which can be automatic and manual operated. All limit switches are non-contacting, they are accurate , relaible and not easily to be damaged, the main electrical components are imported products.

- 2018-01-04 > Vacuum casting equipment

- 2018-01-03 > 4~5t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola

- 2018-01-03 > 7~8t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row cold air supply cupola

- 2018-01-03 > 10~30t/h large distance double row air supply cupola

- 2018-01-03 > Two-shift large distance double row air supply cupola

- 2018-01-03 > Long service life large distance double row air supply cupola